Menu

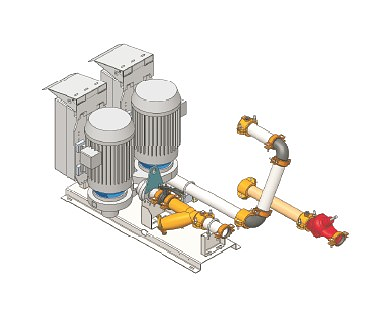

York Integral VSD Hydronic Pump Kit

The new JCI/York Chillers offered on KIG’s site are all from York’s “Stock Chiller Program” with one common set of options which have proven to satisfy over 90% of applications presented to us. These chillers, however, do NOT have internal water/glycol pumps onboard or included. We do offer chillers built-to-order with the hydronic pump package. When compared to providing your own pump with a stock chiller, the price adder for the hydronic pump package will seem very expensive. But, the hydronic pump package is a very sophisticated and well engineered offering including all items below. Many find the savings in field installation costs justify the adder. Lead times for such chillers can range from 10 to 18 weeks depending on model and backlog which often influences a decision. Contact KIG for more details.

York Hydronic Kit Components:

1. Hydronic kit shall be factory installed within the framework of the chiller, lowering additional installation costs and decreasing

floor space occupied by mechanical equipment.

2. The hydronic kit shall include features such as:

a. Factory-installed Y strainer with a drain port.

b. Factory-installed butterfly shut off valve for servicing pumps.c. Factory-installed Armstrong 4392 pump with two drain ports on the lower side of the casing.

d. ¼” NPT fitting for field provided venting device.

e. ¼” NPT fitting for factory-installed thermal dispersion flow switch.

f. Flow Trex Combination Valve, including shut off valve, check valve and balancing capability.

3. The unit with the hydronic kit shall have single point power, reducing installation time and cost.

4. The hydronic kit shall have remote on/off control through the chiller micropanel.

5. Hydronic kit piping and components shall be heated and insulated for freeze protection.

6. Hydronic kit shall use variable speed drive (VSD), which:

a. Reduces commissioning time needed to balance the system.

b. Saves energy when used in variable primary flow arrangements.