Menu

Closed Loop Packaged Chiller w/ 0 psi flow return

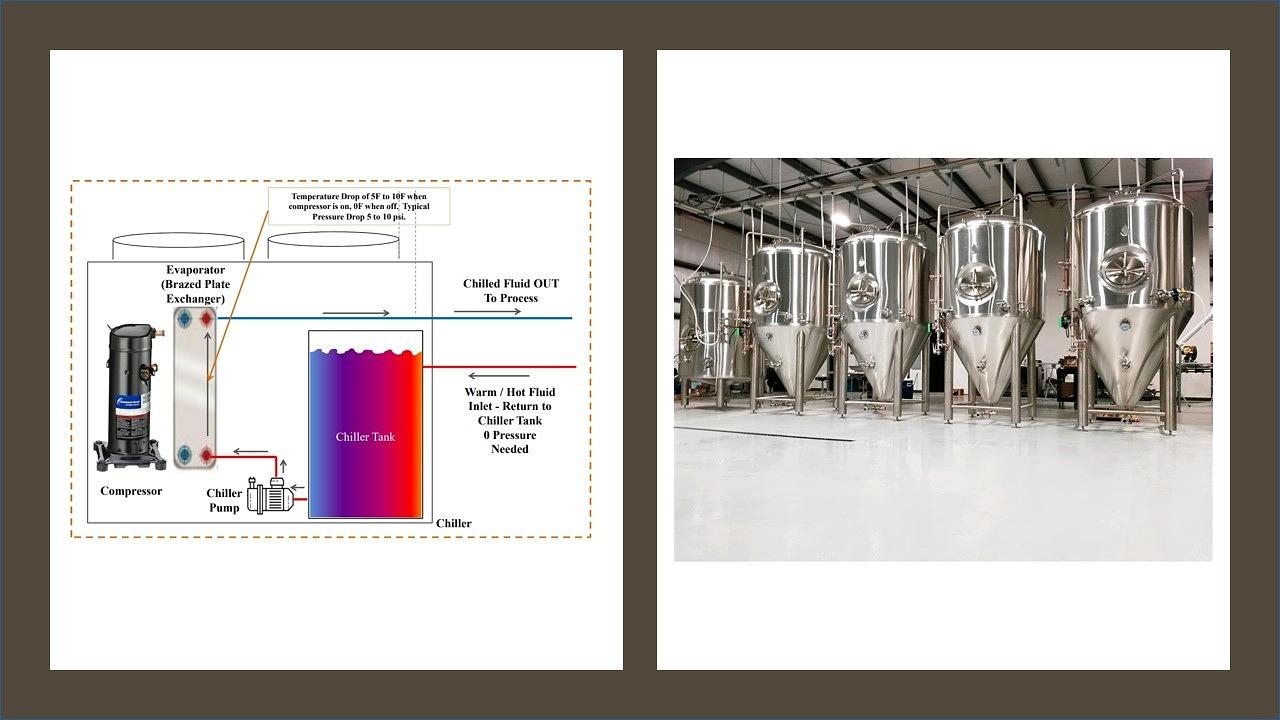

Most of the packaged closed loop chillers KIG has manufactured in the 5 to 30 ton range are piped with a “0 psi flow return” back to the chiller. A packaged closed loop chiller has a pump and reservoir internal. By piping the flow direction per below and as shown in attached pdf, the maximum amount of flow pressure is utilized for your process and concerns about low flow problems coming back to the chiller are eliminated.

Flow:

a. The pump draws/suctions from the internal tank

b. > the flow is then directed through the chiller’s internal evaporator / heat exchanger

c. > the flow is then directed out from chiller, to the process

d. > the flow from the process returns back to the reservoir tank, where 0 psi is needed as it is effectively acting like a drain into the tank

This configuration is ideal when servicing multiple jacketed tanks that have solenoid valves opening and closing based on temperature demand.