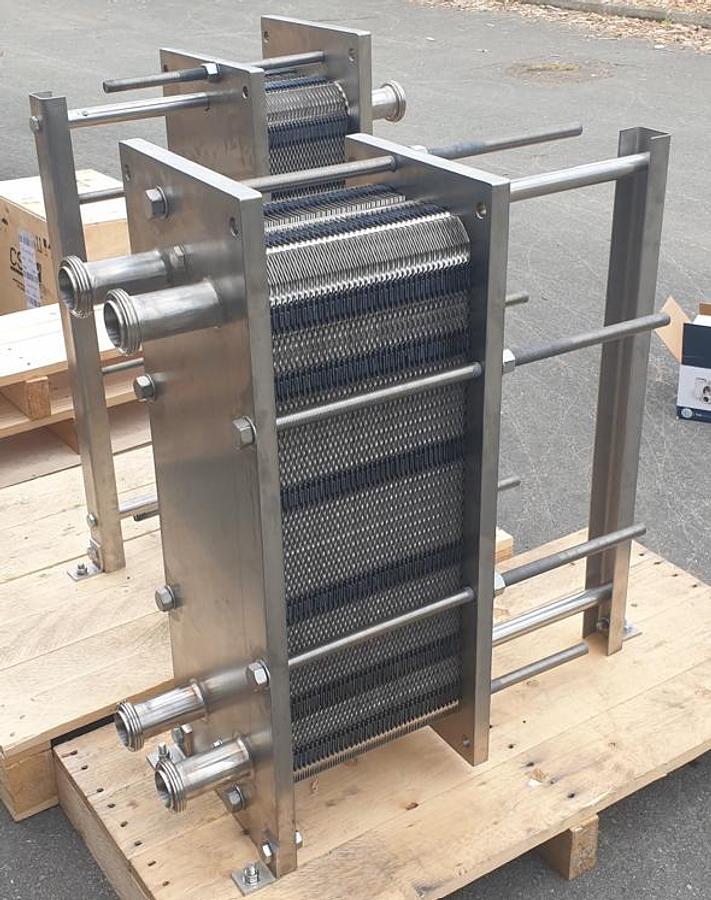

Plate Frame Heat Exchanger

Plate Frame Heat Exchanger

Contact us for price

Description

For some applications, a separate heat exchanger is required to work with the chiller to isolate the water or process loop from the chilled water/glycol loop. Some common reasons for this are:

* Process Water needs to get below ~ 40F. Straight water cannot flow directly into a chiller below these temps. This is because the refrigerant temps in the chillers evaporator/exchanger will be ~ 15 to 20 degrees F colder than the desired the temperature of the water. Freezing and potential rupture of the chillers evaporator would result. The chiller loop would be a glycol concentration going through the glycol side of the heat exchanger.

* the process water/fluid that needs to be cooled is dirty, and a heat exchanger isolates the chiller’s water/glycol loop from the process loop.

* Brewery or beverage applications.

The Plate Frame Heat Exchanger is popular option as it’s cleanable and expandable.

Specifications

| Manufacturer | KIG |

| Model | Heat Exchangers |

| Year | 2025 |

| Condition | New |

| Stock Number | 00089 |