Brazed Plate Heat Exchanger, 5" x 12", 40 Plate

Brazed Plate Heat Exchanger, 5" x 12", 40 Plate

$345 (USD)

or

Call 978-514-3800

Description

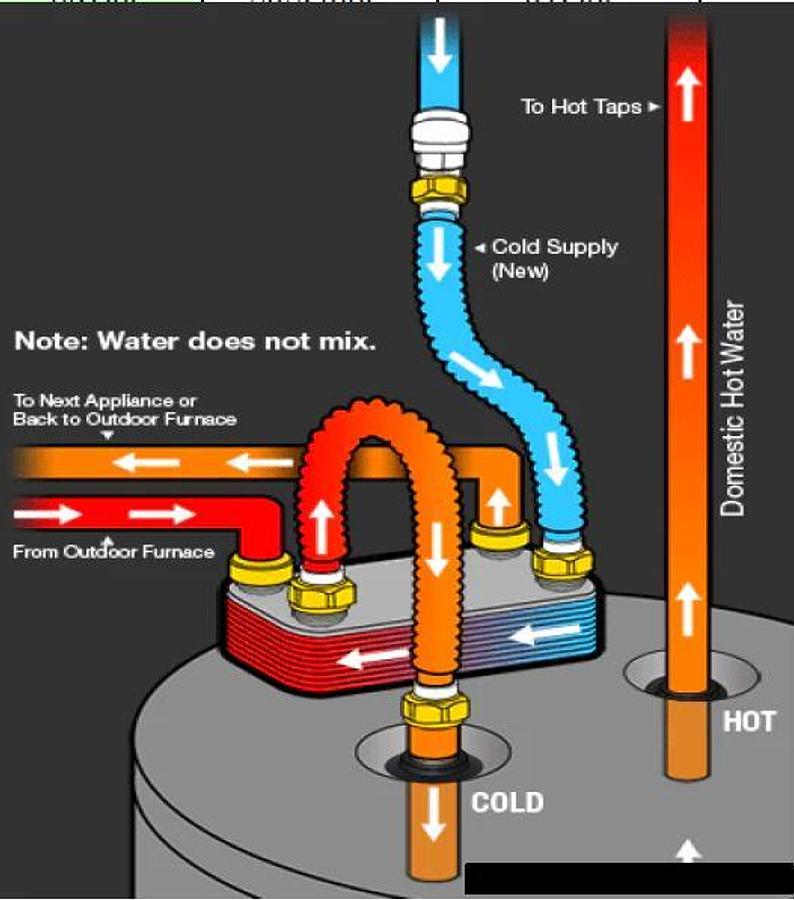

For some applications, a separate heat exchanger is required to work with the chiller to isolate the water or process loop from the chilled water/glycol loop. Some common reasons for this are:

* Process Water needs to get below ~ 40F. Straight water cannot flow directly into a chiller below these temps. This is because the refrigerant temps in the chillers evaporator/exchanger will be ~ 15 to 20 degrees F colder than the desired the temperature of the water. Freezing and potential rupture of the chillers evaporator would result. The chiller loop would be a glycol concentration going through the glycol side of the heat exchanger.

* the process water/fluid that needs to be cooled is dirty, and a heat exchanger isolates the chiller’s water/glycol loop from the process loop.

* Brewery or beverage applications.

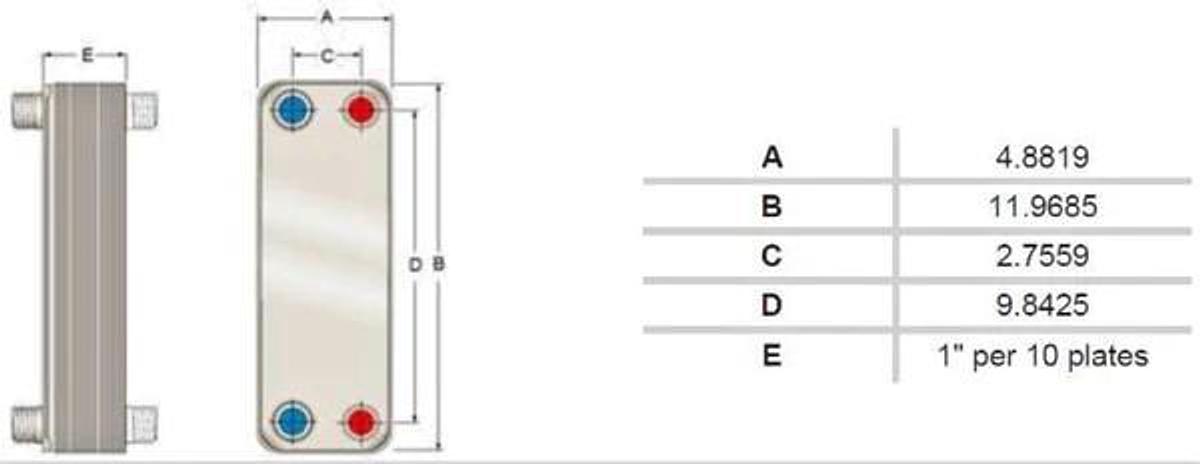

- Material: Plate material: stainless steel, Brazing material: Copper.

- Type: Liquid-to-Liquid

- Connections: 1" NPT ports

- Design Pressure: 652 psi

- Test Pressure: 971 psi

- Design Temperature: Up to 437 °F

- Approvals: UL Listed

Keith Industrial Group, Inc. 104 Sterling St , Clinton, MA 01510

Specifications

| Manufacturer | KIG |

| Model | K0512-40 |

| Year | 2025 |

| Condition | New |

| Stock Number | 00098 |

| Size (W x L): | 5" x 12" |

| # of plates: | 40 |